Biplane rigging

|

|

|

1:32 Biplane Rigging with fishing line

Rigging is probably the most often cited reason why modelers don't build biplanes. This is really a shame as rigging is not that difficult, once you actually try it. Here, I will attempt to show one of the easier ways to tackle this issue - the "fishing line" method.

For this method, we simply need to drill holes part way into the top wing, and through the bottom wing rigging attachment points. For the model used in this example (Gloster Gladiator), I also drilled though the horizontal and vertical tailplane rigging attachment points. When drilling the holes, you should attempt to drill them at the angle the rigging will be at, although this is not crucial to success - in fact I drilled holes straight through in this example to show how easy it is.

Prior to starting the rigging, I painted and decaled the fuselage/tail of the model, leaving the upper wing off to facilitate the rigging process. I did not put the final clearcoat on (only over the fuselage decals to protect them) as we will be touching up the wings and then applying the final clearcoat and weathering once rigging has been completed.

1) These photos show the start of gluing the rigging line (I used 3.2kg/7lb fishing line for 1/48 scale) into all the holes for step 1. 2) Now for the fun part, RIGGING! I placed the upper wing on the fuselage, leaning it between the windscreen and the cabane struts.

3) I started out from the center and worked towards the wing tip, running each line through its appropriate hole in the bottom wing, doing one side, then the other.

4) One should take care not to tangle the lines up, and ensure you are consistent on each side as to what line is on the inside/outside for lines that cross each other... Here all the rigging is in its appropriate holes in the bottom wing (sorry for the fuzzy photos).

5) Now I glue the upper wing to the cabane struts, and then put the outer struts in place on each side. Check to make sure everything is lined up, and here we are – now it is starting to look like we’ve accomplished something!

6) Now I will let the wing struts dry, and the next step will be to tighten all the rigging, by pulling it tight through the hole and putting a drop of superglue to hold it in place. Here I am using some clamps to pull the rigging lines tight, after applying a small amount of superglue to the holes.

7) Suspended to pull the cabane strut support wires tight.

8) And finally, here is the model with all the lines tightened.

9) Next, I trimmed off the excess with a fresh blade.

10) After cutting the excess off.

11) Sanding and filling to get rid of the remaining superglue and holes.

12) To finish off, I repainted the silver on the top of the upper wing and bottom of the lower wing (as well as on the rigging lines), then put some Future on and applied the decals.

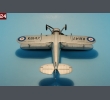

13) Once decaling was done, I sprayed a coat of Model Master Semi-Gloss on to achieve the proper sheen. Here she is finished off as a member of No.3 Squadron at Kenley.

14) As you can see, this method is not difficult and really adds to the finished model, and can be used for any scale with success. Note that these photos are from the very first time I tried this method :) I've since completed more models using this method and it was even easier each time I tried it!

Doug Nelson, September 2011